The industry of aluminum framing is seeing growth at this time, with the extrusion market projected to experience growth of 8.87 million tons by 2025. That is a 5 percent growth above the previous forecast. There are a number of reasons for this. Developers of aluminum framing such as Mini Tec Aluminum Framing will say that aluminum extrusions offer more benefits than their steel counterparts.

They are more lightweight, sustainable, and affordable. They also last longer than steel. Learn more about the many uses of aluminum framing in manufacturing today.

Uses of Aluminum Extrusions

One reason that the aluminum extrusion market is growing is its growing use in the automotive industry. Many automakers are using it in new electric models. This is because aluminum is lighter, and makes for a lighter electric car. Aluminum extrusions in the automotive industry have resulted in energy-efficient vehicles that are just as aesthetically pleasing as those without them.

The use of aluminum framing in the automotive industry is expected to grow as much as 30 percent within the next decade. Aluminum frames are anticipated to comprise 16 percent of the total weight of a vehicle.

How are Aluminum Framing Extrusions Made?

Aluminum frames are popular in the automotive industry, and they are becoming more popular in other industries for the same reasons automotive is using them. The way they are made is appealing to manufacturers, and the durability and quality of aluminum make them much easier to use as well.

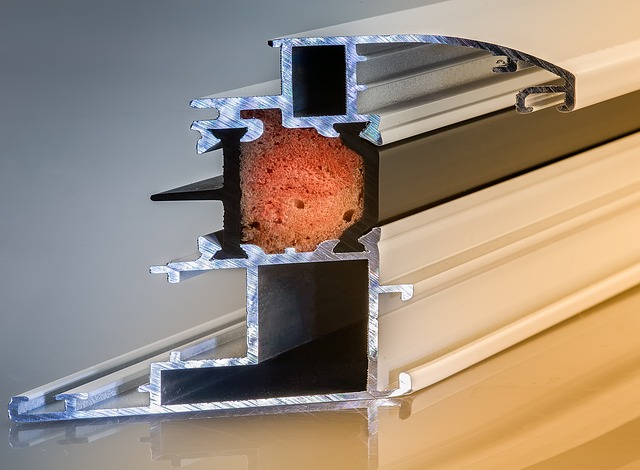

These extrusions are made in a very similar fashion to the old fun dough factories that children use. A die is used to form a mold. The aluminum is pushed through the mold, and the shape of an aluminum frame is the result.

The most common form of the aluminum frame is the T-slot frame. They are available in a wide range of colors and alloys. It is possible to have them custom-made or designed with holes on either end if you are attaching accessories to them, as most applications do.

Many designers will use a 3D printer to create their own accessories such as brackets. However, if you find a quality producer of aluminum frames like Mini Tec Aluminum Framing, they will often carry the framing in a range of colors with their own accessories.

Get a Quote

Aluminum frames and extrusions are a more sustainable and energy-efficient product than steel, and that is why they are being used in multiple applications today. The market is seeing growth due to their increased use in manufacturing designs such as the automotive industry. If you want to bring aluminum framing into your design work, get a quote from a reputable dealer today.