Every business is always trying to improve their efficiency, manufacturing or otherwise. In general, a more efficient approach to manufacturing helps a company to improve their offerings, lower costs, and achieve their green initiatives.

Of course, these general benefits extend to various other positives down the road. These vary from an increase in sales numbers to enhancing a company’s brand image.

With so much that can be gained, there are many reasons to explore ways to improve the efficiency of your manufacturing processes. This guide lists a number of key tips to keep in mind.

Invest in modern software

If you haven’t done so already, the first step to take is to invest in specialist modern software that’s designed for the manufacturing industry. With software such as that offered by servicegeeni.com, it’s possible to handle various processes – such as stock management, scheduling, and asset management – with relative ease.

This type of software should serve as the foundation for your manufacturing company. It allows you to stay organised, improve processes, refine workflow, and so much more. Ultimately, it makes your business a whole lot more efficient.

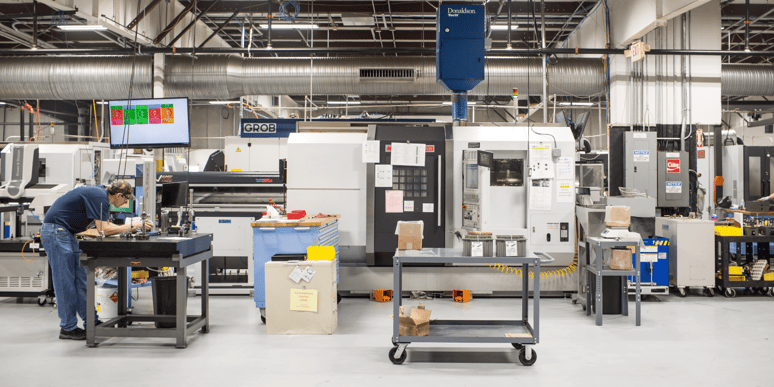

Invest in new machinery

It’s not just software you want to inject money into for your business. It’s also highly recommended you invest in new machinery when appropriate.

Yes, new equipment typically requires a large expenditure. Yet the exceptional increase they can provide to efficiency levels, including the possibility of advancing automation – and consequently reducing employee output – is worth the investment in the long term.

Rather than sticking with old machinery, the type that will negatively impact efficiency over time make sure you continue to plan ahead by frequently investing in new technology.

Preventative maintenance

Even with new equipment, there’s still a requirement for maintenance to be performed. Yet there’s no need to wait for tools to display prominent wear and tear or even breakdown. This is where preventative maintenance should be incorporated into your operations.

As the name suggests, preventative maintenance is used to track the performance and condition of equipment on a regular schedule. Why is this necessary? By identifying and tackling potential issues before they’ve occurred, this can save you a lot of downtime – and money – when any machinery does fail and require replacing.

For preventative maintenance to work correctly, this requires you to stick to a schedule. This is where specialist software can help, as it allows your engineers to know when to perform maintenance checks.

Push for sustainability

By-product is a natural occurrence during the manufacturing process. This waste is also something that can eat into your profit margins. With the rules and regulations that need to be met, disposing of this waste is expensive and time-consuming.

As a result, you should be pushing towards sustainability and cutting down on waste production. It’s not only about saving money and improving efficiency, either. A more sustainable approach is beneficial in more ways than one. Not only does it help the environment, but it also reflects well on your business. This makes it worthwhile.