The organization needs not only to improve products, but also to improve and optimize logistics business processes, so that costs can be reduced and quality can be delivered to the customer.

The trading system, regardless of its type, is a set of connected business processes with one end goal such as Sales and profit-making; products are goods, services, as well as documents, and information. A business process consists of internal and mutually dependent functional activities.

Types of Business Processes

The following types of business processes can be distinguished:

- Product sales process (horizontal type), which brings benefits to the business system.

- Planning and management process (vertical type), which provides income from the application of horizontal business processes of product sales.

- Resource processes (vertical type), ensure the delivery as well as the storage of the product directly at the point of action.

- Transformation process (vertical type), additional process (auxiliary), which is necessary to change existing technologies.

Business and Logistics Processes

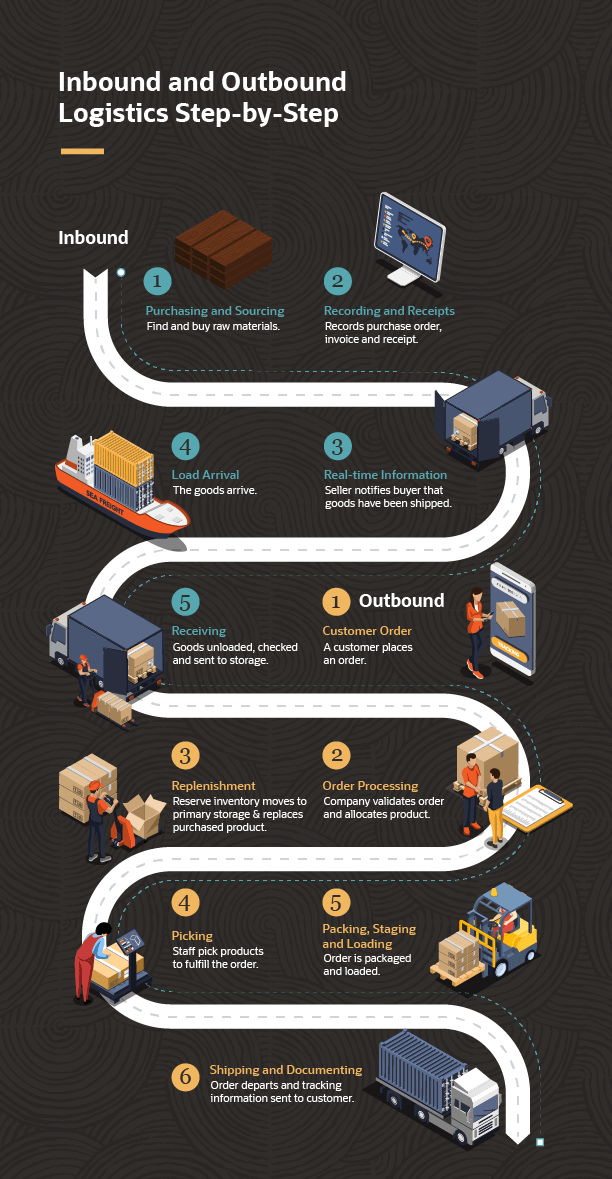

- The business processes of logistics include:

- Product movement planning (part of the planning and management process).

- Delivery of the product by the manufacturer or supplier (part of the resource process).

- Maintenance of the warehouse account of the cargo received (a part of the resource process).

- Delivery of goods to stores (part of the sales process).

- Control of the flow of basic goods (part of the planning and management process).

Roles of Logistics in Business Processes

- Within the aforementioned business processes, the logistics service performs functions such as:

- Coordination of the date of receipt and shipment of the goods.

- Analysis of available transport data.

- Determine the best delivery route.

- Estimation of the basic indicators of transport costs .

- The preparation of a map of transport routes.

- Designing a batch delivery systems plan.

- Receiving and storing the merchandise in the warehouse.

- Shipment of goods from the warehouse.

- Informing the recipient of the arrival time of the transport with the cargo.

- Record of orders received from stores.

- Transfer of goods from the reserve status to the expedition.

- Putting a mark on the invoices.

- The register of the returned goods.

- Continuous monitoring of the product path.

- Control over the processes of receipt, shipment and return of merchandise.

Much depends on well-organized logistics, ranging from the timely supply of raw materials for production, the shipment of finished products, to the delivery of the products to the final consumer in a timely manner and at the lowest cost.

Business Process Reengineering

One of the modern technologies of business management is business process reengineering technology.

Reengineering is a basic rethinking and radical redesign of business processes to achieve sharp and rapid improvements in modern business performance, such as cost, quality, service and pace. Its use in practice allows many companies to: reduce the cost of production at the expense of increased management efficiency, increase the quality of production, reduce the processing time of customer orders, and quickly develop new production and so on.

The General Scheme of Business Process Reengineering:

The business process model is developed the existing process model in the company in question is developed, and its technology is also registered.

On the basis of the analysis of the given model, an outline of the new processes (“as it should be”) is made with the development of new technologies.

The model together with the technologies of the new processes, undergo a careful analysis of compliance with the basic requirements of the trading system, during which the potential economic benefits are calculated.

The model of new processes is introduced in the practice of the company’s activity (provided that the positive results of the analysis are received).